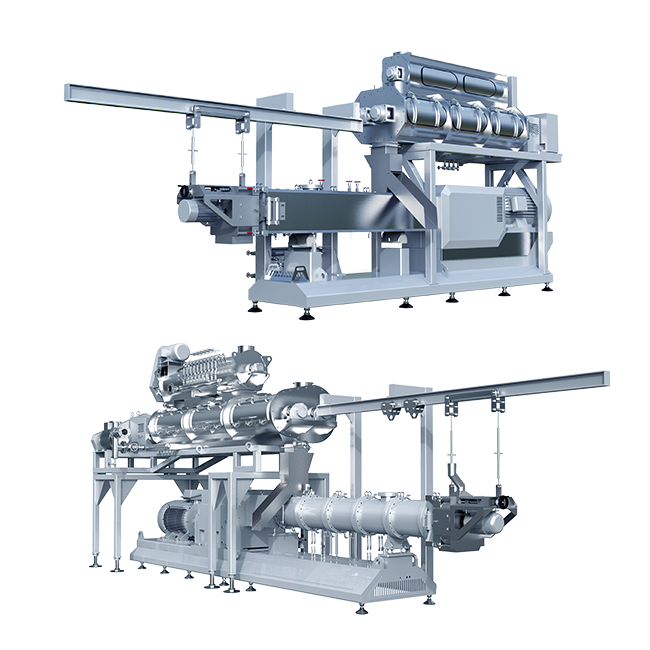

In the world of food processing, the Twin-Screw Aqua Extruder by FAMSUN stands out as a revolutionary technology. Designed to meet the demanding needs of modern food production, this machine ensures high efficiency and quality in the extrusion process.

High-Precision Gearbox for Optimal Performance

At the heart of the FAMSUN food extruder is its advanced gearbox, meticulously designed and processed according to European and American standards. It adopts 5th grade high-precision gears that guarantee effective transmission, significantly enhancing the operational stability and reliability of the extruder. Coupled with first-class brand bearings and oil seals, this gearbox not only optimizes performance but also prolongs the overall lifespan of the machine. The service life of the new wear-resistant alloy screw reaches an impressive 4000 to 5000 hours, making it a long-lasting investment for food manufacturers.

Enhanced Production Capabilities

The Twin-Screw Aqua Extruder is specifically engineered to cater to various food processing needs. Its unique design allows for precise control over the extrusion process, resulting in superior product quality. This food extruder is ideal for producing a range of aquatic feeds, snacks, and other textured food products. With FAMSUN’s innovative technology, food manufacturers can achieve higher output rates while maintaining the integrity of their ingredients. The robust construction and reliable features of this extruder make it a preferred choice in the industry.

Conclusion

In summary, FAMSUN’s Twin-Screw Aqua Extruder represents a significant advancement in food extruder technology. With its high-precision gearbox, durable screw design, and enhanced production capabilities, this machine is poised to revolutionize food processing. By investing in this trusted food extruder, manufacturers can ensure efficient operations, superior product quality, and increased profitability in a competitive market.